Sponsored article

Forming Plywood and MDF with HF Technology

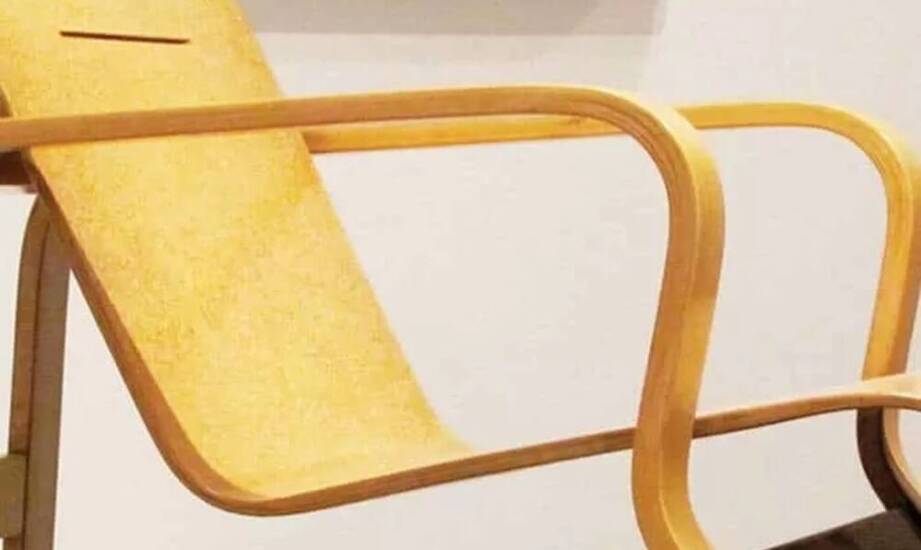

The modern approach to forming plywood and MDF using high-frequency (HF) technology and hydraulic presses is revolutionizing the production of wood-based materials. Efficiency and cost-effectiveness are becoming crucial for manufacturers, especially in the context of short production runs. It is worth exploring this technology and understanding the advantages of modern solutions and the benefits of using machines in the forming process.

Read more: Basic types of sealer machines

The Process of Forming Plywood and MDF

The production of plywood and MDF begins with obtaining wood fibers from various tree species, which are then bonded with resin. Forming plywood occurs under pressure and high temperature, allowing for the creation of panels with desired properties. Thin layers of wood are arranged crosswise, ensuring greater dimensional stability and resistance to external factors. High-frequency technology enables internal heating of the material. As a result, manufacturers can fulfill orders faster and with less energy consumption.

Read more: What is a priming emulsion and what is its purpose?

Advantages of High-Frequency Technology

Unlike traditional methods, high-frequency technology (HF) allows for internal heating of the material, significantly speeding up and streamlining the entire process of forming plywood. Its application in hydraulic presses offers several benefits, such as:

-

Shortened production cycle times – faster forming leads to higher efficiency,

-

Energy savings – more efficient power use reduces operating costs,

-

Reduced raw material usage – precise forming minimizes material waste,

-

Improved product quality – a stable process ensures consistent and aesthetic results,

-

User-friendly operation – modern control panels simplify operators' work.

HF technology is an ideal solution for plywood and MDF manufacturers seeking reliable, modern, and economical processing methods.

Application of Hydraulic Presses

Hydraulic presses with HF technology are used in many production processes. The flexibility of these machines allows for the forming and gluing of wood-based materials using various types of adhesives, including thermosetting ones. High quality and consistency in forming plywood are guaranteed by machines produced by Zemat Technology Group, ensuring that companies can execute even short-run orders without concerns about quality loss or cost increases. This is the perfect solution for businesses operating in competitive markets where flexibility and quick responses to customer needs are key to success.